The total number of strokes in each round amounts to half when you consider two strokes per hole per green. Therefore, 36 strokes each round occur on the putting greens! Design and renovation of the putting surfaces is serious business and directly linked to the success and popularity of each hole we design. At Schreiner Golf, Inc. we have been involved in renovation work on some of the finest greens in the world.

Slope, size, angle, shape and location are five of the major design elements that impact the development of a putting surface. The heart of every hole is its green. Distance, bunkers, elevation changes and advancements in club and ball technology can all be balanced and neutralized with a properly designed putting green.

The design process is the same for each hole, however, the final result should be different for each green. This is very important to us assures each client that the replication of the same green will ever occur. That is an indispensable quality of approach to golf course design. The greens are the DNA of a golf course and the heart of each hole.

Modern green construction and genetically altered Bentgrass have made slope tolerances very tight regarding the slopes of greens. High speeds resulting from low cutting heights has placed a premium on specific gradients in the surfaces of green. We understand these tolerances and design beautiful putting surfaces that can be used under the quickest of speeds without compromising flagstick locations and loosing valuable surface area.

Engineered surfaces that surface drain in different ways combined with a natural look are the qualities that give putting greens an artistic flair. This is called 'form follows function' in design terms. In golf terms it is called the green for the length and severity of the hole. It starts with accurate drawings and finishes with a jeweler's polish.

The art and science of greens design is refined with accurate drawings that are critical to keeping costs inline and quality at the forefront of the project. When restoring great classic golf holes, such as the first green at Donald Ross's Belmont CC in Belmont, Massachusetts, engineered details are the basis for true restoration combined with field refinements for aesthetics, character development and play quality.

New greens are no different. The 2nd hole at Westwynd, in Rochester Hills, Michigan, offers the golfer a double green located below the clubhouse. These greens are historic in nature and evolved through from the oldest course the world, St. Andrews. They are difficult to locate in the proper setting without 'forcing' them. This process requires very intricate hole routing to develop one putting surface that can be used many different ways from two holes.

"New greens are the most exciting aspect of golf course design. With each new hole an opportunity arises to create something that has never been done, a putting surface unlike any other that will challenge and reward smart skilled play."

- Craig Schreiner, ASGCA, ASLA

This perspective shows the terrace that separates the 2nd

hole portion of the double green from the 18th hole at Westwynd. Double

greens are not as common as they used to be due to safety issues.

Restoration of old greens is important to preserve the finest examples of golf course architecture. Re-grassing is not uncommon when upgrading a facility. The surrounding environments of old greens are often negatively impacted by the placement of trees. The 6th green at the Country Club of Buffalo, designed by Donald Ross, was recently improved by removing trees from behind the green. The original concept was to have a putting surface that had a 'Skyline' profile and challenged the depth perception and wind play of the golfer. The before and after shots here depict the dramatic difference in the hole's evolution.

Each hole has a set

of criterion that insures its uniqueness and instills variety. The 6th

green on the South Course at the Westfield Companies CC offers two-level

green on this short 320 yard hole, which is reachable for the lower handicap

golfer.

The

3rd green on the South Course of Firestone CC in Akron, Ohio is a great

example of our ability to design a small green with maximum flagstick

locations in a difficult micro-climatic area and not loose turf quality

and shot value.

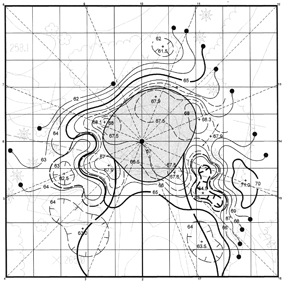

This

Green Detail holds Contractors to 1/2" tolerance in surface slope

and 1% in the surface area. The axis of the green and angle of the green

are controlled from by our approach as well. Severity and variety are

adjusted in the field.

From

this side the 2nd green at Westwynd Golf Course looks south to the 18th

portion of the double green.